Before I get into the story, I think the blog post name including the date and the loco will be a good way to organise these blogs. It will be easier to search and view by loco project...there are a few currently on the go!! Somehow less dull than "loco update, loco update, loco update"!

OK, back to the Britannia...

The grates needed a trim off the length and few notches out of the corners to fit the firebox but after that was done, they sat in the correct place. They sit on the ashpan and a ledge at the front, with the ledge trimmed in the centre to allow the centre portion to drop down. The firebox tapers in all directions and it was a trick to get the bits in place and also removable through the ashpan hopper. I hope it's a success, it will be only able to be dumped in the steaming bay where access is possible between the tracks.

Those that have been following this build have seen the original Winson design and also the Norman Spink design have grates that are made from bars and spacers, with a dropping portion in the centre forward half.

The problem I forsaw with this scenario is the grate is trapped in and can't be removed without pulling the loco apart, a real pest if it bent or burnt out by clinker and strange coals we are getting these days! The whole thing was under designed from a maintenance perspective.

The grates now in position are made from stainless steel water cut plate, tapered bars and all. (If you want one, get in touch with us as our supplier has all the right gear). The grate is in 3 portions, the centre section is entirely removable and so makes room to get the other side portions out through the middle.

The next thing to sort out is how to keep the middle portion in place. I'd thought of the conventional cross pin underneath the grate but I don't think it's the easiest to line up with the holes in the ashpan as its a long way across. Also prone to bending over time. Plus it's another challenge to hold the grate up while trying to put the pin through! I must have piano fingers nice and slender, some other blokes have kranskys!

So the play time yesterday involved making a swinging stand under the centre grate that will sit on a ledge in the ashpan. Also helps removal as the stand can be used to pull the grate out and put it in.

One of the challenges I face in model engineering is visualising a solution that will work in all cases as a standard fix, less time designing an easy-to-use solution will be a big plus. I think the stand under the centre grate may be a goer, I'd like a bit of feedback as to how it performs in service!

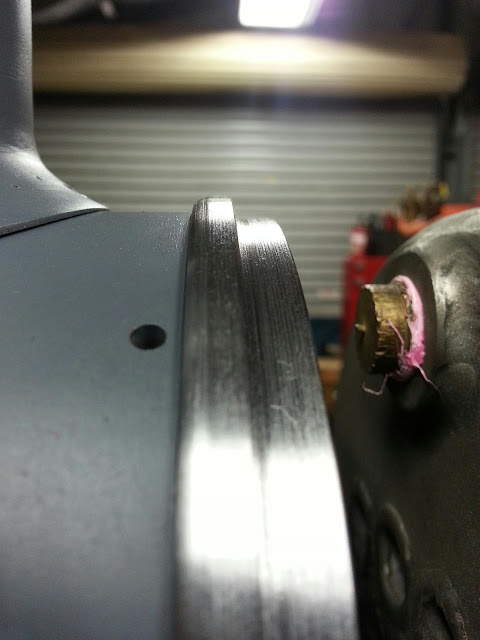

Below are some pics looking through the firehole...