After the throatplate seams were cleaned up they were checked over for penetration. A good fillet on the inside satisfied me that it was all in good order and can now look at getting the dome onto the boiler barrel.

The dome flanges were machined from hollow gunmetal and drilled and tapped for the stainless capscrews. I can see the merit in studs but domes aren't regularly pulled apart so screws/bolts with good thread enegagement is sufficient and saves the work making studs and nuts.

The bottom flange has an o-ring recess which will have a Viton o-ring, to make easy resealing, no gaskets, no goo, and less torque required on the bolts to get the seal. I once repaired a copper dome flange with stripped/pulled threads, required stepped studs and plenty of gasket goo with a gasket to seal it as it was warped from the tension required to get a seal! Wrong material being too soft, not enough thread engagement, and very time consuming to get the gasket goo out from between the studs!

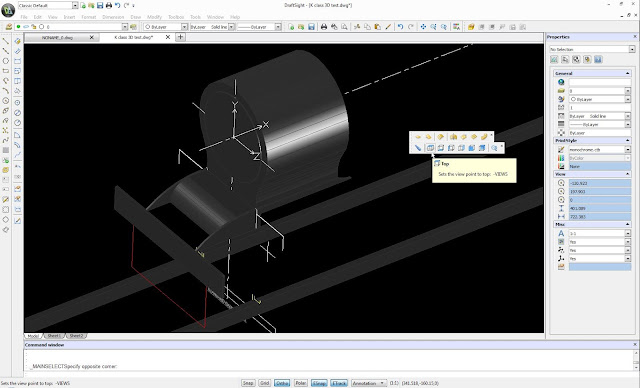

I've also been working on a jig to hold the barrel for setting up in the mill to do the dome flange hole. I'm expecting setting up the boiler in the mill to do the job means the dome flange is going to be square to the boiler from the getgo rather than mucking around with soldering jigs to square up a dome flange in an oversize hand-finished hole. The way copper tends to grab is good reason to get the clamping nice and solid.

Merry Christmas to you all and hope to catch you back again in 2017, let's make it a great year!

Don't forget you can subscribe to our blog to be emailed these updates as well!

Happy steaming!

Nigel